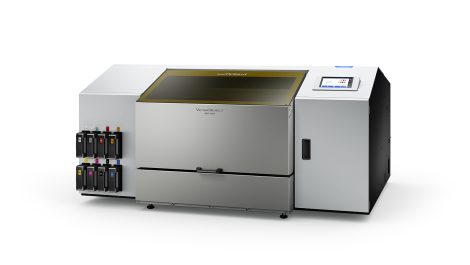

Mimaki has unveiled a significantly faster version of its ‘Kebab’ cylindrical object printing option for its UJF series of flatbed UV printers, the Kebab HS.

Mimaki reports that over 1600 Kebab units are already installed in the EMEA region with an average of one out of five UJF-series printer users choosing to add this option. UJF flatbed printers equipped with a Kebab option can achieve three-dimensional direct-to-object printing, increasing the variety of print applications possible with their printers.

Building on the capabilities of the Kebab MkII, the new Kebab HS increases productivity by three times, taking approximately 10 minutes to print per material, suitable for users handling mid-volume orders with a single printer. It also broadens application possibilities in UV printing further, by allowing personalisation on both cylindrical and tapered items with sloping sides, subject to a maximum angular taper of 7.5 degrees.

Arjen Evertse, general manager sales at Mimaki Europe, commented, ‘Here at Mimaki, we look to constantly innovate our existing products and create added opportunities for print service providers, and the launch of the Kebab HS is one of the latest examples of this. As an optional solution, it allows the users of our popular UJF Series printers to add another dimension to their product offering and up their competitive edge.’

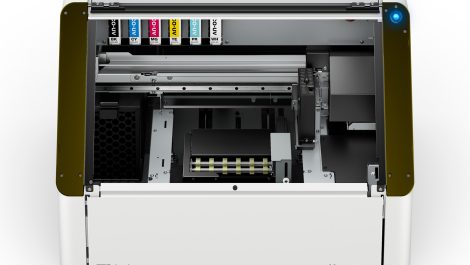

This new Kebab option can be quickly installed, requiring only the attachment of the main unit to the UJF Series print table; certified service engineers are available Mimaki UK and Ireland exclusive distributor Hybrid Services to provide a ‘seamless’ installation. The current Kebab MkII and Kebab MkII L will remain available and are recommended for printing on smaller diameters (50mm or less) and items longer than 280mm.