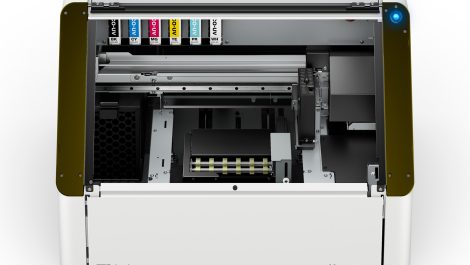

Lasting Impressions (Signs) of Bridport, Dorset has installed a Gibson GTF-2512R flatbed printer and Almeida B8-2513 digital cutter, both supplied by SOS, to bring increased productivity in its production of health and safety signage.

Prior to the new installation, jobs on rigid media such as plastic, vinyl, Foamex, Correx, PVC or acrylics would either have been screen printed, requiring a minimum quantity of around 50 to make the set-up economically viable, or roll-printed on a Roland solvent printer that required 24 hour degassing before lamination and mounting. With the digital print and cut setup, there is no minimum order requirement and the need for laminating onto materials is removed as the Gibson printer works directly on the substrate.

Owner Terry Gall explained the choice of equipment thus: ‘We hadn’t heard of Gibson before but were very impressed at the demo site we visited. Compared to the alternatives it’s cheaper to buy, but what’s surprised us is how cheap it is to run. The inks cost less than screen printing or solvent inks, and we’ve calculated the power consumption is way less than expected, at about £6 a day.’

The Almeida cutter was an important part of the package, too. ‘We used to buy materials cut to size, but now we can print multiple signs in one pass and the cutter does the rest. It’s also really versatile, we can change the blades, cut all kinds of shapes, sheets of stickers, and more,’ confirms Mr Gall.

The company is now looking to expand the range of applications it can support, and with half the work coming via web orders, is well-positioned to spot emerging trends and opportunities. One potential application is in Braille printing of signs, with the raised characters produced by layering the white ink in the printer.

‘All together we’re expecting this machine to contribute to a big rise in turnover in the coming year,’ notes Mr Gall.