Leeds-based print, direct mail and fulfilment specialist RNB Group has praised the impact of a triple finishing equipment purchase from Friedheim International, revealing that the investment has helped to significantly improve production flexibility.

Founded in 2005, RNB works with hundreds of organisations across a number of industry sectors to deliver a wide range of specialist services such as print, direct mail, ecommerce, operational mail and data solutions.

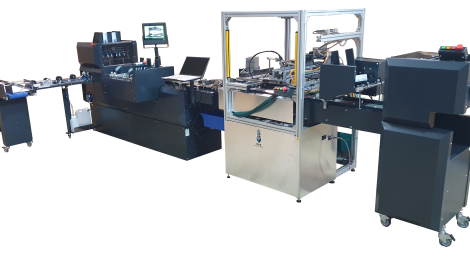

After speaking with Friedheim International, RNB settled on a triple purchase from the print finishing equipment specialist: a Hunkeler Unwinder UW6, Spedo 8500 E Stacker with tray (second user) and Spedo 2600 Pinless Cutter 2600.

The three machines have been in place for months now, with the company’s project and account manager Dave Martin claiming the triple purchase has made the finishing process at RNB significantly more flexible, freeing up staff to take on other work.

Mr Martin said, ‘The devices have allowed us the flexibility to produce more with less down time, while they have also helped to streamline our paper-to-envelope time. The investment has also reduced the number of touch points in finishing, freeing up staff in the process.

‘The result of this was an immediate increase in productivity, which is what we expected when placing the order. Simply put, it has allowed more flexibility without breaking down kit.’